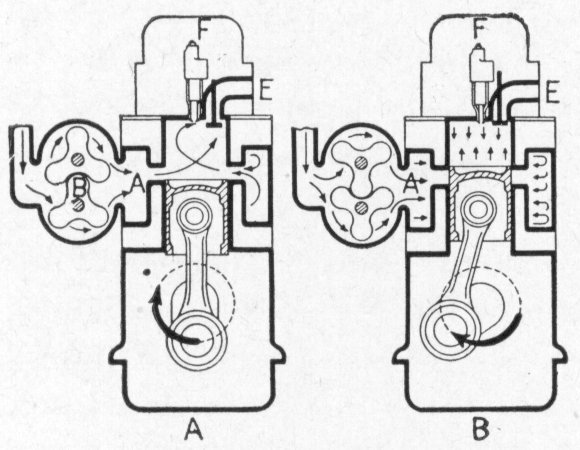

When the piston is at bottom dead center, as shown in A, air in the header A at about 5-lb. pressure flows through ports into the engine cylinder. The air sweeps up into the cylinder and forces from it all burned gases; these gases along with some of the air escapes through the exhaust E by way of the exhaust valve which is opened by a cam (not shown) driven by gears from the crankshaft. There are four exhaust valves in each cylinder head, although only one is shown.

The crankshaft continues to rotate, and the piston moves up and, by passing across the air ports (called "scavenging ports"), prevents more air from entering the cylinder. At the same time the cam closes the exhaust valves, as shown in B.

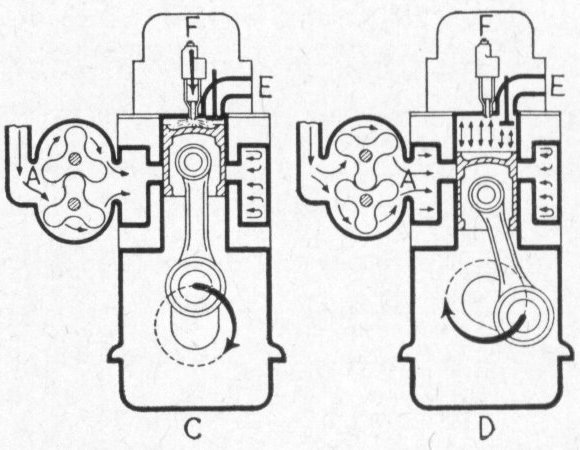

Ignition occurs at once, and the gas pressure rises sharply. This pressure forces the piston down as shown in D. Here the piston is almost in a position to permit air to enter through the rows of scavenging ports, and the exhaust valves have already opened.

The cylinder gases start to pass out through the exhaust E. As soon as the scavenging ports are free, air blows into the cylinder, while the piston moves from the position shown in A to that shown in B. In this way all the burned gases are forced out of the cylinder, and the cylinder is charged with fresh air.

The advantage of this system of scavenging is that the flow of air and of burned gases is in one direction, from bottom to top, so the cylinder is well cleared of burned gases, and the engine is able to burn a high rate of fuel per cubic inch of cylinder volume.

This page last updated on 6-6-2001